Generator Installation Budget Guide: Cost Breakdown and Influencing Factors

Why Budgeting for a Generator Matters + Outline of This Guide

Power outages are more than an inconvenience—they can spoil food, halt home offices, interrupt medical devices, and add stress during storms. A standby or portable generator can restore normalcy, but the price tag is rarely a single number. It is a layered sum of equipment, skilled labor, permits, fuel infrastructure, and site work that changes with your home’s layout and local codes. Getting the budget right at the start keeps the project grounded, prevents surprise change orders, and ensures your system is sized and installed safely. Think of this guide as the map that turns a foggy estimate into a clear, defensible plan.

Here is the outline of what follows so you know exactly where we are headed before we dig into numbers:

– Cost buckets and how a realistic price spectrum forms in the real world

– An itemized breakdown with typical ranges and sample budgets

– Key factors that push costs up or down (you can influence many of them)

– Ownership and operating expenses beyond day one

– A step-by-step budget method, savings levers, and a closing checklist

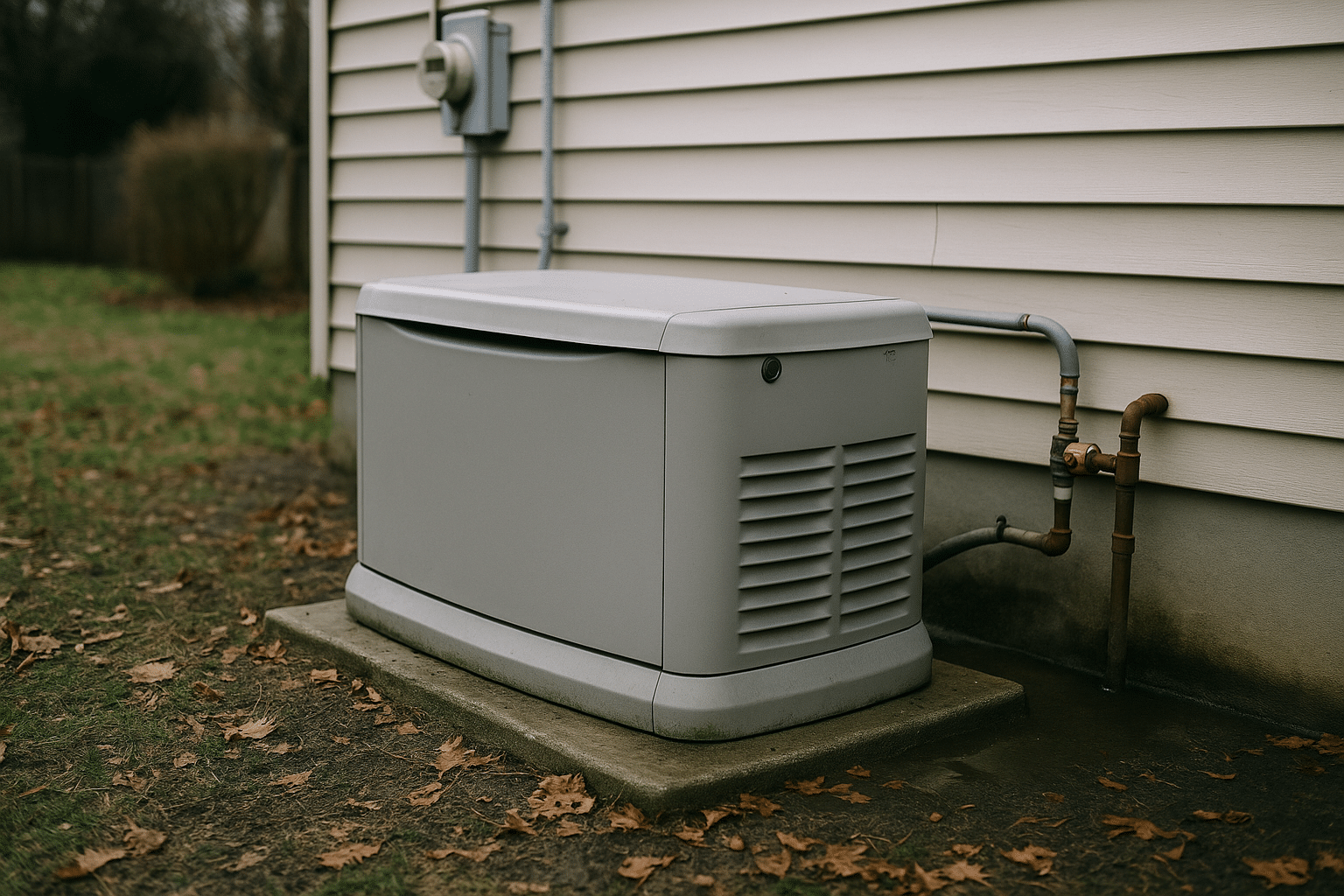

Before the line items, a quick orientation. Portable units, often on wheels with manual connection, can cover essentials at a comparatively modest price. Standby systems, typically fixed on pads with automatic transfer switches, aim for whole-home or large-load coverage and involve electricians, plumbers (for gas), trenching, and inspection. The range is wide: many households spend a few thousand for a safe, code-compliant portable setup, while a turnkey standby project can climb into five figures. Understanding why those numbers spread is the key to choosing a solution that fits your tolerance for downtime, your house’s infrastructure, and your budget.

Cost Breakdown: From Hardware to Handshakes

Budgets become credible when they are broken into parts. A complete installation usually includes the generator, transfer equipment, electrical work, gas work (for natural gas or propane), site preparation, permits and inspections, accessories, delivery, and contingencies. Each of these has a predictable price pattern, and combining them paints a realistic total.

Typical line items and national-range ballparks:

– Generator unit: portable 2–8 kW at roughly $500–$2,500; standby 10–26 kW commonly $3,500–$7,500 (larger capacities scale up).

– Transfer equipment: manual interlock or inlet components $150–$600; automatic transfer switch (ATS) commonly $400–$1,500 depending on amperage and features.

– Electrical labor: $80–$150 per hour; total $800–$3,000 for portable setups; $2,000–$6,000 for standby (panel work, ATS wiring, load testing).

– Gas work: natural gas tie-in or new propane line $500–$2,000; adding a buried propane tank can add $1,500–$3,000 for the tank and placement.

– Site prep: concrete pad or compacted base $200–$600; trenching for conduit/gas typically $10–$20 per linear foot.

– Permits and inspections: $100–$500 depending on jurisdiction and whether both electrical and gas permits are required.

– Accessories: cold-weather kits, battery warmers, sound baffles, or wifi modules $100–$700 combined.

– Delivery, rigging, and disposal: $100–$400 depending on access and equipment.

– Contingency: add 10–15% to cover unknowns, code-driven tweaks, or minor scope growth.

Putting components together, here are simplified examples:

– Essentials-only portable: inlet, interlock, outdoor-rated cable, and a 5–7 kW unit. Installed totals often land in the $1,200–$3,800 range depending on labor rates and panel complexity.

– Mid-size standby (14–18 kW) for partial or near whole-home: equipment $4,500–$6,500; electrical labor and ATS $2,500–$5,000; gas work $800–$2,000; pad and trenching $300–$1,000; permits and misc $300–$800; contingency $700–$1,500. Aggregate totals frequently fall between $9,000 and $16,000.

– Larger whole-home standby (20–26 kW) or long runs/trenching: project totals can reach $12,000–$22,000+, especially with lengthy conduit routes, meter upgrades, or a new propane tank.

Numbers swing with house age and layout. A short, straight conduit run from the generator to the service panel costs less than rerouting around patios or under driveways. Likewise, integrating with an older panel may require upgrades before the ATS can be installed. The point is not to inflate the budget, but to reveal the pieces that create it—so you can value-engineer intelligently rather than cut corners that matter for safety.

What Drives Costs Up or Down: The Influencing Factors

Several levers determine where your project lands in the spectrum. Generator capacity (kW) is the first. Size is dictated by total running and starting loads for the circuits you want to power. A refrigerator might only draw a few hundred watts while running, but compressor startup can briefly spike multiple times higher. Stack those surges across HVAC, well pumps, sump pumps, and cooking appliances, and capacity needs can climb. Most households aiming for essentials coverage find 5–8 kW portable units workable; partial-home standby systems often sit in the 10–18 kW band; larger homes or all-electric houses may look to 20–26 kW and beyond.

Fuel type also shapes both installation and operating expense. Natural gas offers convenience where a supply line already exists, requiring a pressure/volume check and a branch line to the unit. Propane works where gas utilities are absent, but may require installing or leasing a tank. Gasoline is typically for portable units and commands regular refueling and storage considerations. Diesel appears in higher-capacity or rural use cases, with robust torque and longer run times but heavier equipment. These choices influence line-item costs (gas plumbing, tank placement) and future fuel budgets.

Home infrastructure and site conditions play a major role:

– Electrical service: a crowded or outdated panel may need a subpanel or service upgrade, adding $1,000–$3,000.

– Distance and routing: each extra foot of conduit or gas line, obstacles like patios or retaining walls, and hard soil or rock adds labor and materials.

– Code and permitting: clearance to openings and property lines, elevation above flood zones, and noise ordinances can dictate pad placement or sound mitigation.

– Climate: cold-weather kits or battery warmers help starts in subfreezing temperatures; coastal environments may steer you to corrosion-resistant housings.

– Access: tight side yards or steep slopes can require more labor or small-equipment rigging.

Labor rates vary with geography and demand. After major storms, schedules fill and pricing can reflect overtime or expedited handling. Conversely, planning during a calmer season may yield faster scheduling and occasional savings. Finally, the project scope itself matters: choosing an ATS with load-shedding modules can allow a smaller generator to cover more circuits by staging loads, trading a modest control-system expense for a smaller engine and lower fuel burn. In short, capacity, fuel, infrastructure, code, and scope discipline are the dials you can turn.

Beyond Day One: Operating Costs, Maintenance, and Lifespan

An installation budget is only the beginning. A generator’s value shows up (and sometimes disappears) in recurring costs you will carry over years. The main components are fuel, routine maintenance, occasional repairs, and the opportunity cost of outages avoided. Estimating these honestly helps you choose the right system and right-size your expectations.

Fuel is the largest variable. Approximate energy cost per kilowatt-hour varies by fuel and local prices, but these ballparks are useful for planning:

– Natural gas: often around 15–30 cents per kWh equivalent for standby-sized units.

– Propane: typically 30–60 cents per kWh equivalent depending on delivered price.

– Gasoline: roughly 25–50 cents per kWh for portable units, sensitive to local pump prices.

– Diesel: commonly 20–40 cents per kWh, improving with efficient, larger loads.

Maintenance keeps reliability high. Expect annual service—oil, filters, spark plugs on many models—in the $200–$600 range for a professionally serviced standby system, with portable units on the lower end if you DIY and follow the manual. Batteries usually last 3–5 years; budget $100–$250 for replacements. A periodic exercise cycle (often 10–20 minutes per week) consumes a modest amount of fuel but keeps the engine lubricated and ready. Every few years, plan for deeper checks: valve adjustments on some engines, enclosure corrosion touch-ups, and transfer switch testing. Good maintenance is cheaper than a mid-storm failure.

Longevity depends on run hours and care. Standby units commonly deliver thousands of hours; for many households that translates into a decade or more of service life. Portables, when run within capacity and stored properly, can last many seasons but may retire earlier if pushed hard or poorly maintained. Consider soft costs too: food spoilage, hotel stays, and lost work hours during outages. If a typical multi-day outage would cost your household $500–$1,500 in spoilage and lodging, a resilient system can pay back over a few events. Empirical math beats guesswork—track local outage history, estimate your loads, and align the system with your tolerance for downtime.

Build a Realistic Budget: Steps, Savings Levers, and Conclusion

Here is a practical, repeatable way to assemble your budget and avoid unwelcome surprises.

Step-by-step method:

– Define loads: list must-have circuits and their running/starting watts; decide whether you want essentials, partial-home, or whole-home coverage.

– Choose fuel: evaluate availability, delivery logistics, and operating cost. If natural gas is present, request a meter capacity check from your utility.

– Establish routing: sketch generator location, conduit path to the panel, and gas line path; measure distances and note obstacles.

– Get written quotes: target at least two licensed electricians and, if needed, a plumbing contractor for gas. Ask for line-item detail and permit fees.

– Add ownership costs: fuel estimates, annual service, and a small reserve for wear items like batteries.

– Include contingency: 10–15% to handle code-driven changes or minor scope additions without stress.

Where to save without sacrificing safety:

– Keep the run short: place the unit close to the service panel while maintaining code clearances and ventilation.

– Right-size with load management: an ATS with load-shedding can often let a smaller generator cover more circuits.

– Prepare the site: handle simple landscaping or a gravel base under contractor guidance, where allowed.

– Time the project: off-peak seasons can mean faster scheduling and occasionally friendlier pricing.

– Buy once: choose equipment sized for foreseeable appliances (like a future heat pump) to avoid near-term upgrades.

Quick sanity checks help. If labor rates in your area average $120/hour and your scope includes panel work, ATS wiring, a 25-foot conduit run, and commissioning, 20–35 labor hours is a reasonable bracket. For gas, a straightforward branch line and leak test may run 6–12 hours. When your quotes deviate sharply from these ranges, ask for clarifications on routing, materials, or code requirements driving the variance.

Conclusion and next steps: A grounded generator budget is not about chasing the lowest number—it is about aligning resilience with resources. By breaking the project into parts, understanding what drives costs, and planning for ownership expenses, you transform a fuzzy estimate into a confident decision. Gather your load list, sketch your routing, and request detailed quotes with line items. Add a sensible contingency and a maintenance plan. With that, you will have a clear, defensible budget and a system ready to keep your home calm when the grid is not.